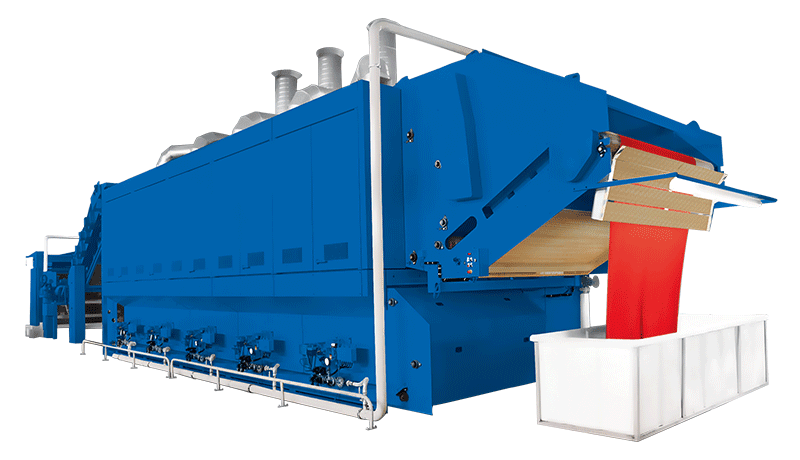

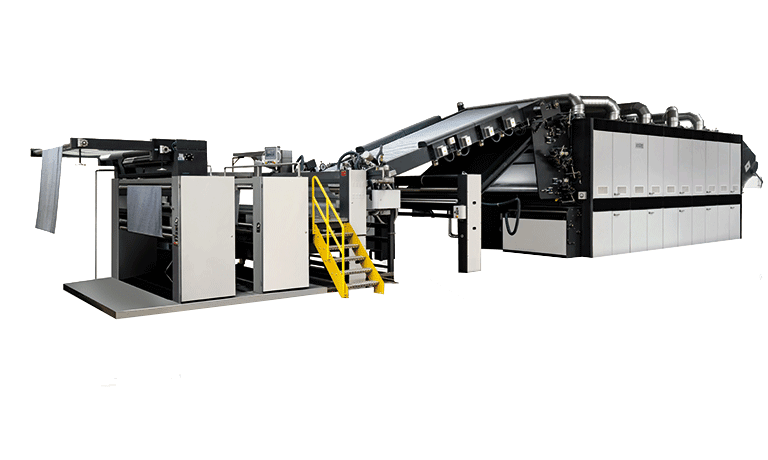

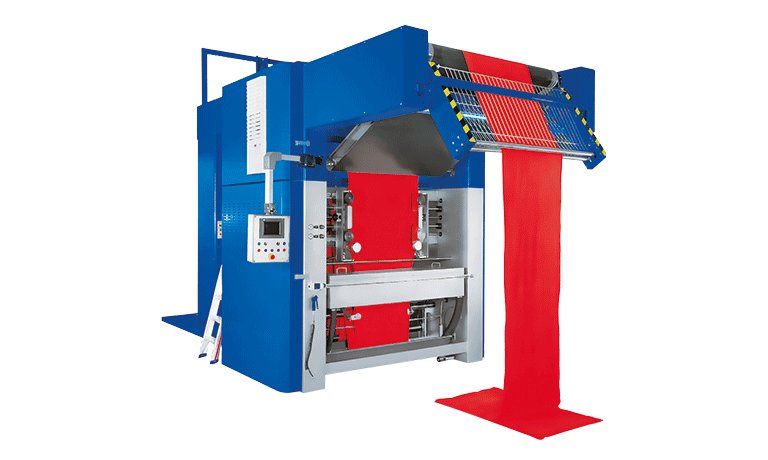

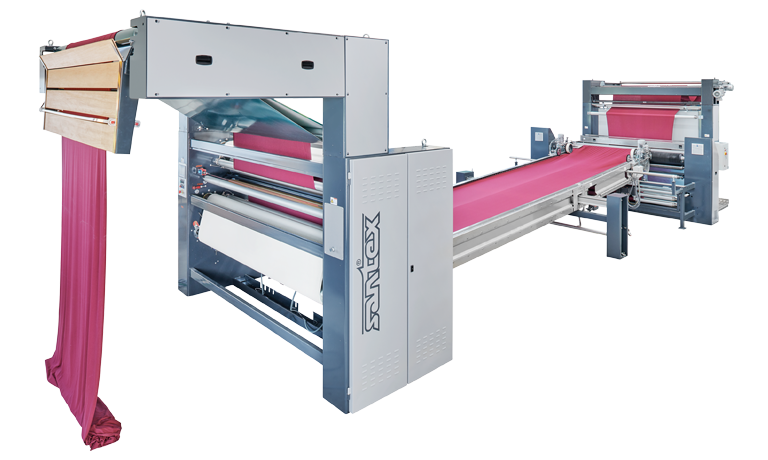

Tensionless drying, shrinking and relaxing

The fabric is laid on the transporting belt at the feeding unit, which includes the overfeeding roller and a special apron. The fabric is ideally guided in wave form through the drier. The nozzle alignment forces the fabric to a fast and intensive drying, which includes tumbling effect. The moisture control in the chambers is optimized for energy saving.

A steaming and vibration chamber enhances the bulkiness and support the shrinkage process. The exit unit is composed of an inclined wooden lathed belt to cool down the fabrics before plaiting. Every chamber is equipped with manual lint filters, which can easily be cleaned during operation. Optionally an automatic lint filter system can be built in instead.

The process control is easily monitored via Santavision, HMI equipped with touch screen panel.