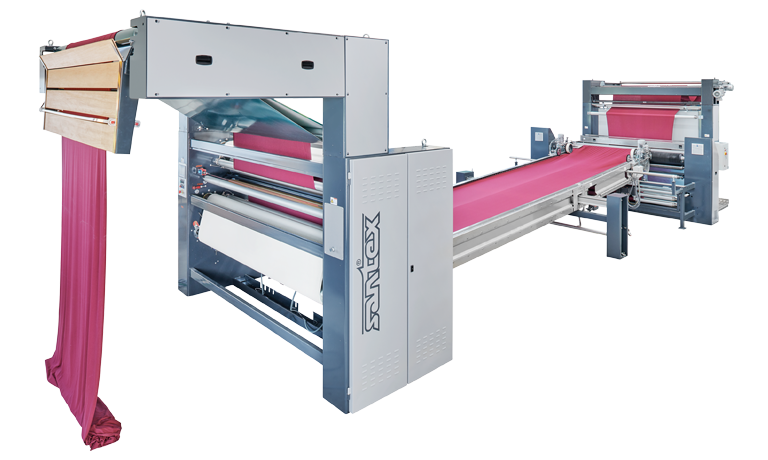

Levelling, steaming and compacting calander

Santex Santacompact RD Plus has this main technical features:

- Equalizing frame with individual chain drive and specially new designed chain

- motor driven middle support

- Tensioneless and disortion-free pinning with short, direct and crease-free feed into the compacting unit

- Condensate-free steam box with compensation for different widths, completely corrision-restistant version

- 3rd compacting zone with large heating roller diameter and specially designed steam box in front of it.

- Specially designed elastic felt belt in all three compacting zones

- Heatbale smoothing and shrinking rollers for a softer touch