DryWa: Innovative integrated system for drying sewage sludge

DryWa technology is developed to make sludge management efficient and cost-effective, respecting the environment and climate.

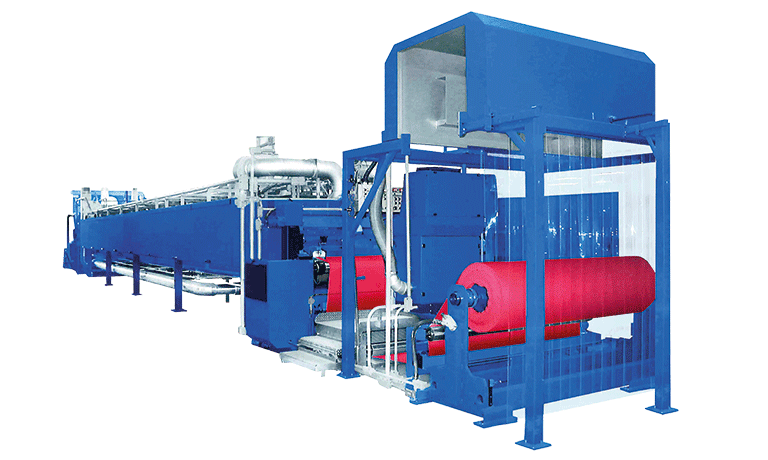

Drywa is the only low temperature belt dryer equipped with a CO2 heat pump.

Compact design, no operative costs for filters and the lowest energy consumption make Drywa 100% green and eco-friendly.

Sewage sludge and sludge from ETP (particularly from Dyeing companies) are perfectly treated by DryWa without odors and air emissions, even without filters.

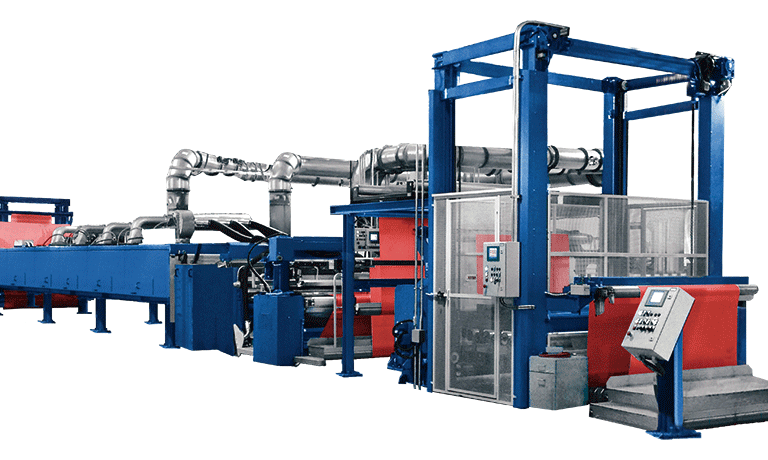

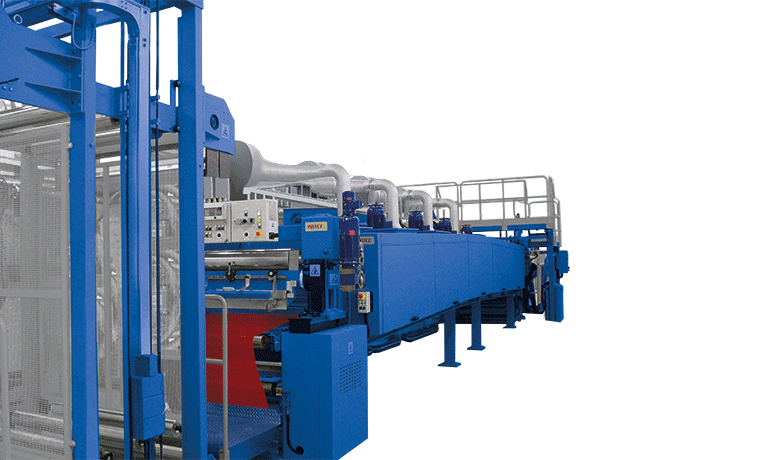

The process is based on a compact technology which can be used also in a series of joint modules.

DryWa is a revolutionary thermal stand-alone system to dry sewage sludge, achieving a 95% of weight reduction in only 15 m² surface (20 ft naval container). DryWa is a system to dry sewage sludge, where the input is the wet sludge (around 25% DM) and the outputs are ashes and emissions into the atmosphere.

A high performance heater inside the system generates the drying process, allowing DryWa to be a stand-alone system in terms of thermal energy. It can be placed directly inside the wastewater treatment plant without any modification. DryWa modules can be stacked into vertical systems, to increase the drying production.