There are two ways to produce Prepregs: Hotmelt-based process and Solvent-based process. Hotmelts reach the necessary viscosity properties for a perfect impregnation just by temperature effect.

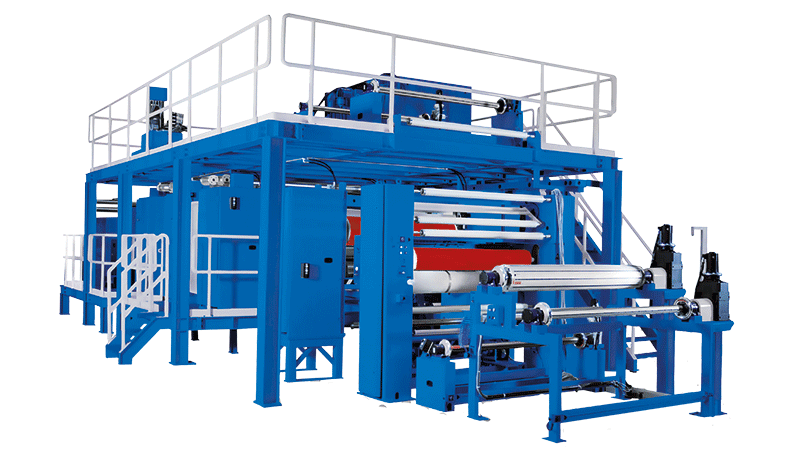

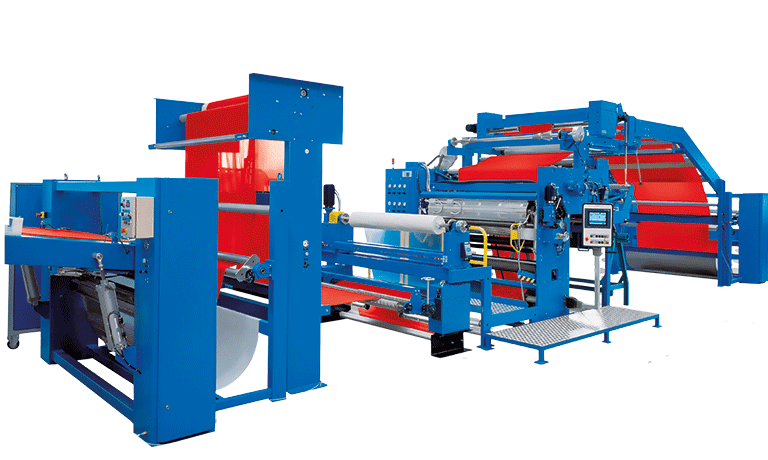

Matrix Film Production (Film Line):

Coating of release paper with resin

Coating by direct roll, reverse roll or knife coating

Impregnation/Transfer (Tape Line):

The reinforcement (UD-fibers of fabric) is between the two release papers

Transfer on the resin from the release paper into fibers, from one or from both side

Saturate the fibers by heating and consolidation

Pre Polymerization

The Prepreg can be produced in off-line mode with a separate film and tape line, or in-line mode with a combined film/tape line

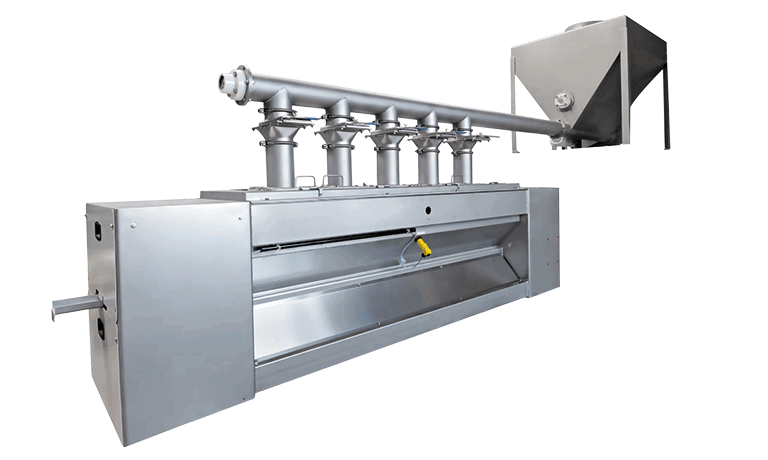

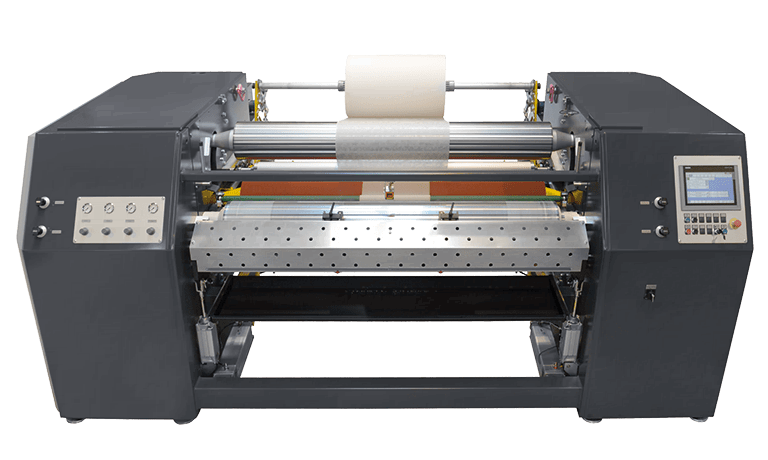

The Solvent-based process is mostly utilized for Prepregs where resin viscosities are too high without adding solvents, even at higher temperatures. The reinforcements are generally fabrics. They are passing a solvet based matrix bath. The resin content is controlled by squeezing rolls. The impregnated substrate is heated in an IR Radiant dryer for Solvent evaporation and pre-polymerization of the resin. Radiant dryers are applying radiation of a specific wave length to enter the substrate, to effect drying and curing form the core to outside.

These two processes are in general applicable for Duroplastic Resin Systems. Thermoplastic Applications are made with the traditional Scatter Coating Process or with Water Based Systems.